Diamond Cutting Tools: Classification, Applications, and Technical Characteristics

I. Classification

(1) Natural Diamond Cutting Tools

Natural diamond, a single - crystal material, forms extremely sharp cutting edges. Its regular atomic structure enables ultra - precision machining.

(2) Synthetic Single - Crystal Diamond Cutting Tools

2.1 High - Pressure/High - Temperature (HPHT) Synthetic Diamond Cutting Tools, Single crystal synthetic diamond MCD diamond tools

HPHT synthetic diamonds are made at 5 GPa and 1500°C. Early ones were amber due to nitrogen doping, which could enhance wear resistance. Now, white HPHT diamonds are used in tool - making at a higher cost.

2.2 Chemical Vapor Deposition (CVD) Synthetic Diamond Cutting Tools

CVD technology emerged in the 1980s. Initially polycrystalline, single - crystal CVD diamonds are now mass - produced. Grown in a vacuum, they’re consistent, stress - free, and free of natural diamond defects.

(3) Other CVD Diamond Cutting Tools

These tools deposit diamond films on substrates, balancing cost and performance. They’re suitable for aerospace ceramic - matrix composites.

(4) Polycrystalline Cubic Boron Nitride (PCD) Cutting Tools

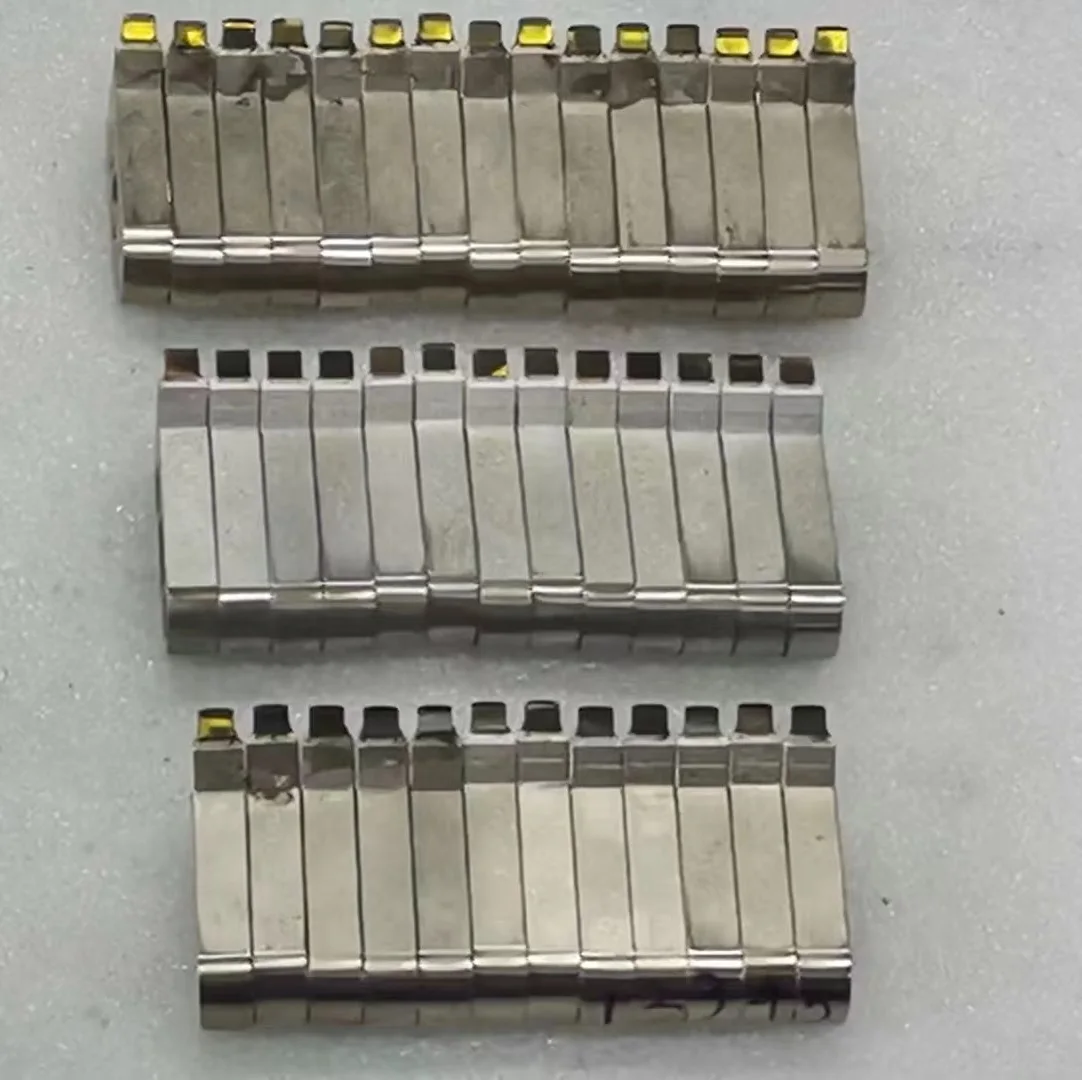

PCD tools, sintered from diamond micropowder and binders, are cost - effective with good wear and impact resistance. They’re used for automotive aluminum parts and circuit boards.

II. Applications

(1) Medical - related Lens Industry

Diamond tools accurately process contact and intraocular lens materials, ensuring optimal visual performance.

(2) Jewelry/Watchmaking Industry

They cut gemstones, carve precious metals, and machine watch parts for accurate timekeeping.

(3) Eyeglass Lens Tool Industry

Diamond tools produce high - precision eyeglass lens tools, improving lens quality.

(4) Aerospace Industry

Diamond tools ensure the machining accuracy of aerospace components like turbine blades, enhancing engine performance.

(5) Electronics and Information Industry

In semiconductor manufacturing, they cut wafers and process packaging materials, reducing chip damage.

(6) Automotive Manufacturing Industry

For automotive aluminum engine parts, diamond tools enable high - speed cutting, cutting costs and extending engine life.

(7) Electro - optical Industry

Diamond tools process optical glass and quartz, enhancing the optical performance of laser lenses.

III. Technical Characteristics

(1) High Hardness and Wear Resistance

Diamond’s hardness helps diamond tools resist wear, prolonging tool life and cutting costs.

(2) Excellent Thermal Conductivity

High thermal conductivity allows diamond tools to quickly dissipate heat, minimizing thermal deformation.

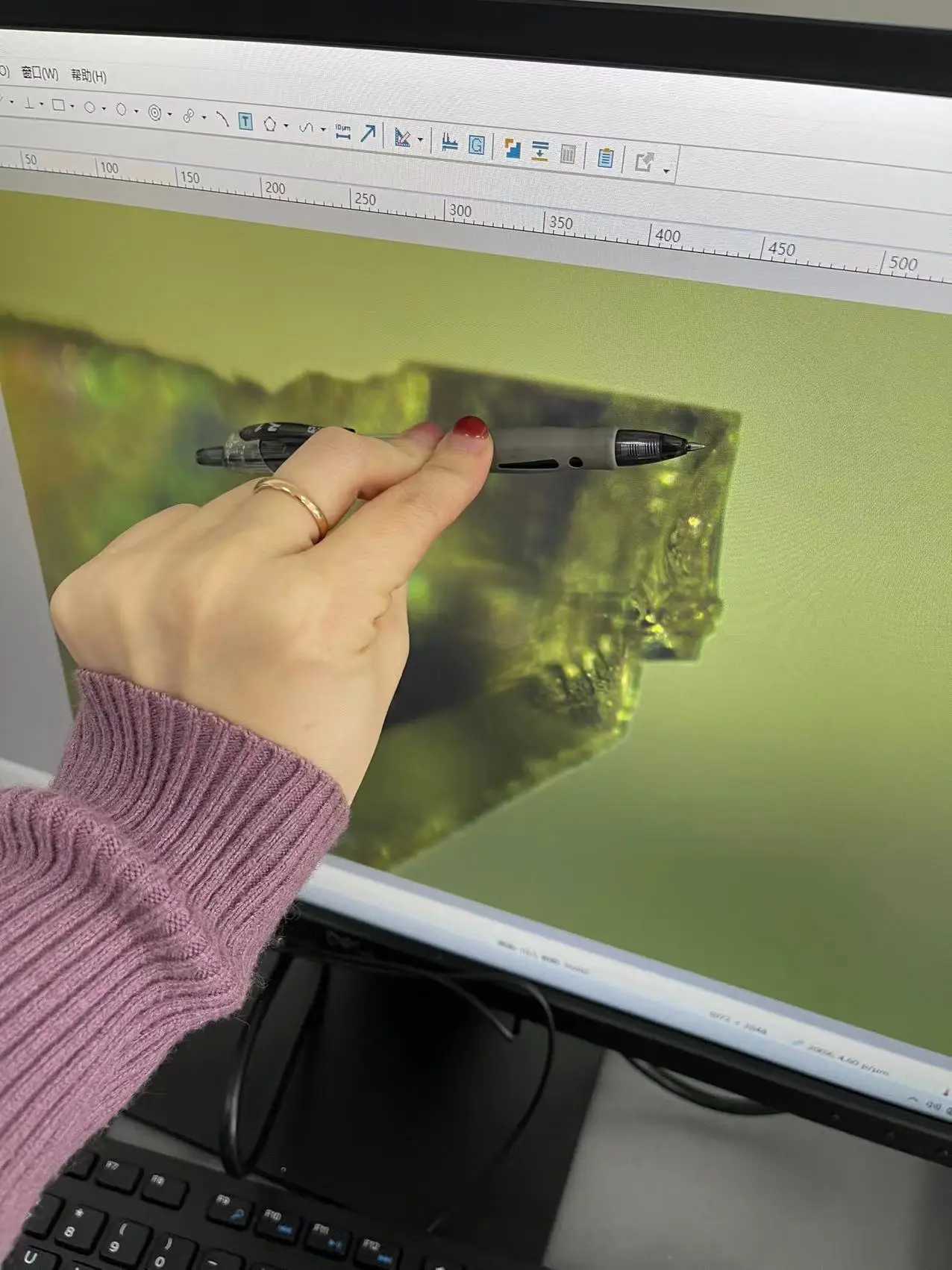

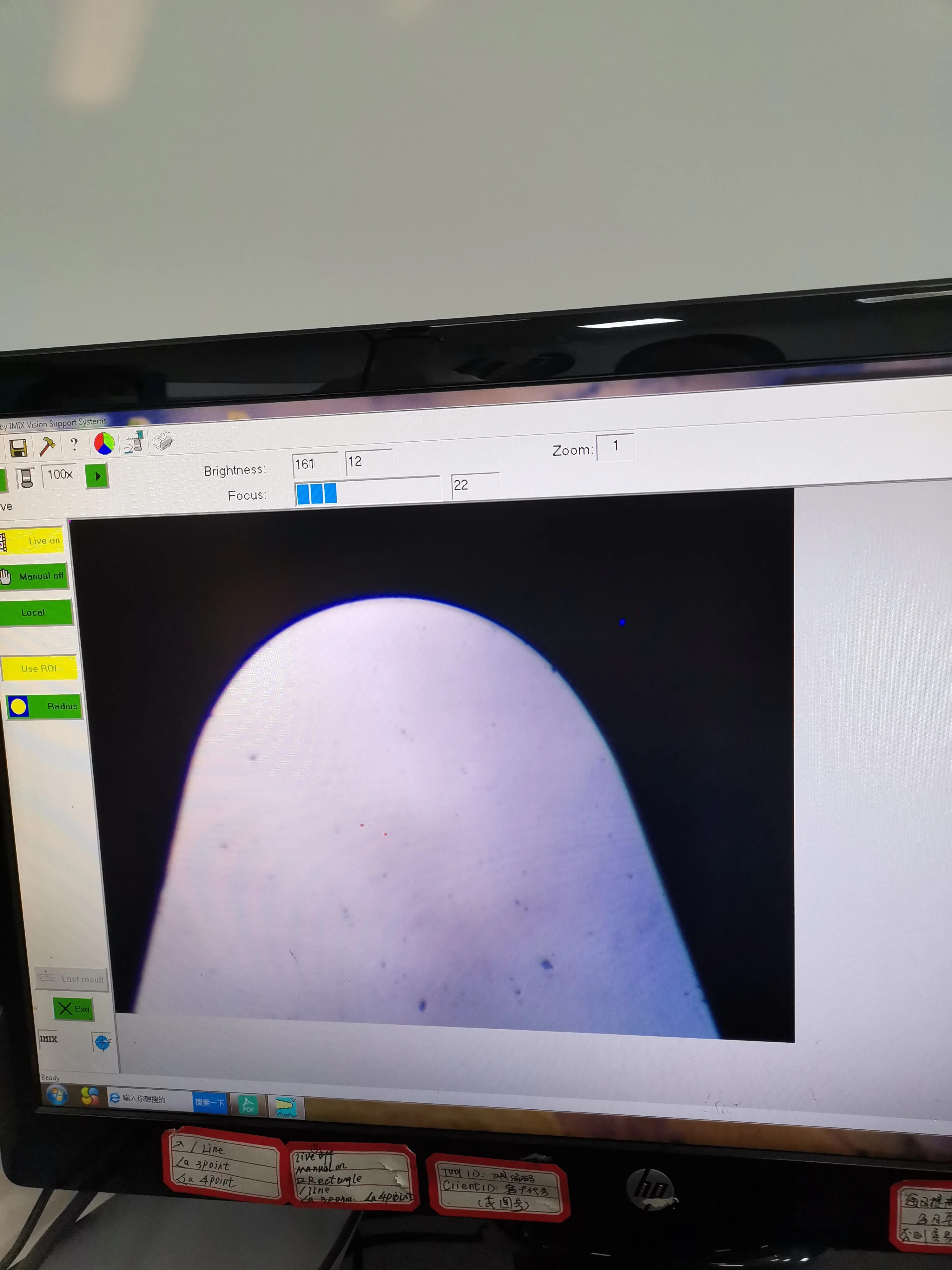

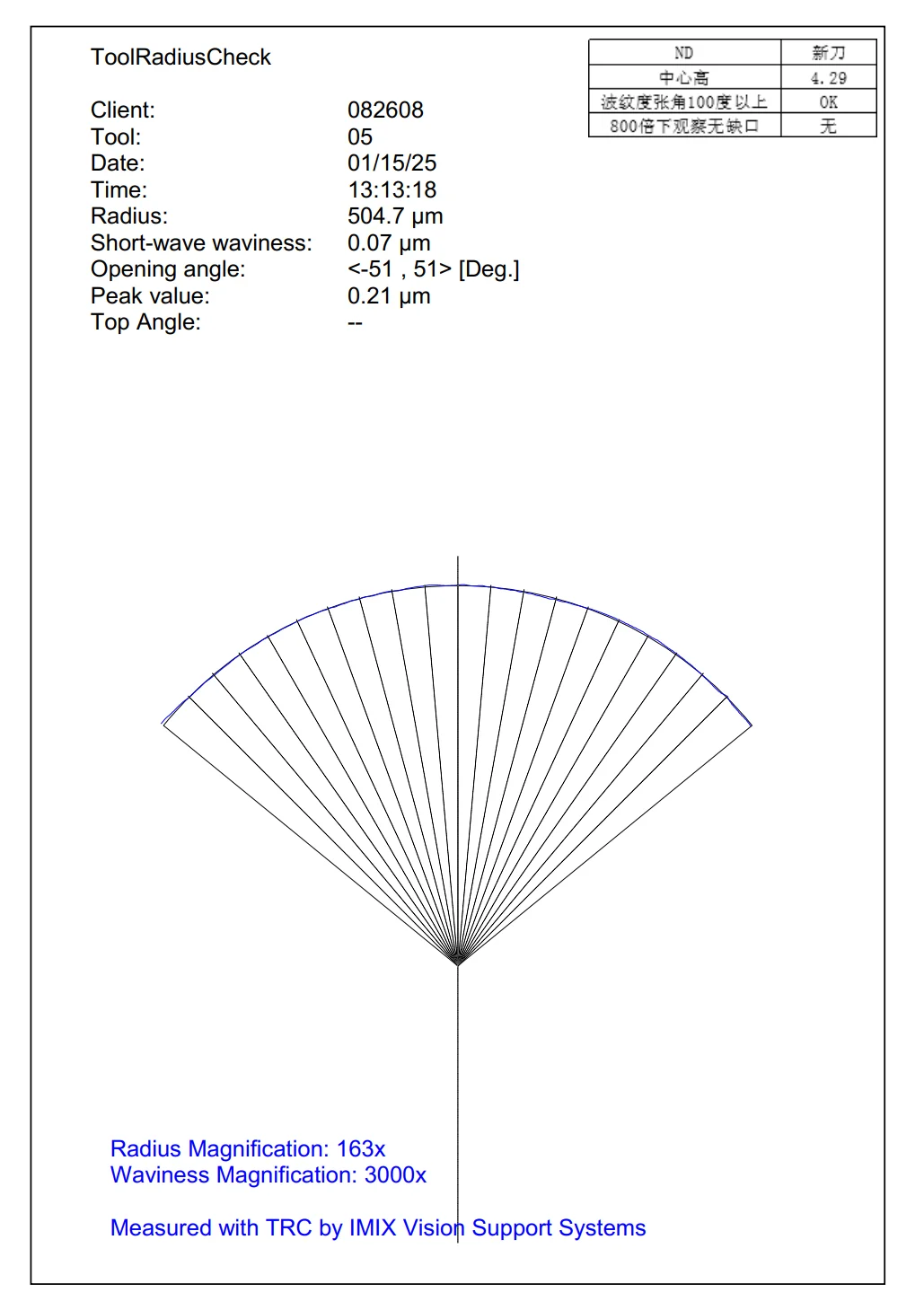

(3) Sharp Cutting Edges

Sharp edges enable ultra - thin cutting, achieving a great surface finish for ultra - precision machining.

(4) High Machining Efficiency

High hardness and wear resistance allow diamond tools to operate at high speeds, boosting efficiency.

| Customized support | OEM, ODM |

| Place of Origin | China Shanghai |

| Usage | Internal Turning Tool |

| Hardness | Diamond |

| Transport | TNT\DHL\ Fedex\ EMS\ UPS |

| HRC | HV10000 |

| Shank Diameter | 3-20mm |

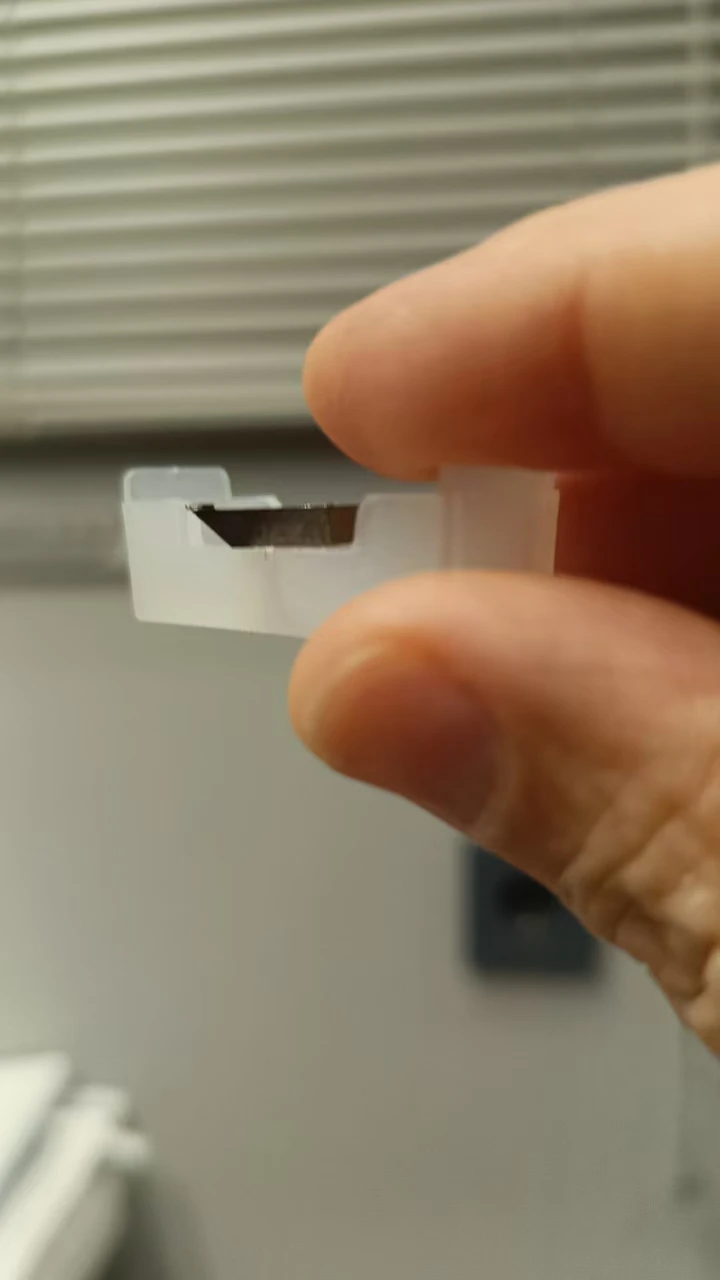

| Packing | 1ps/ Plastic Box |

| OEM | Welcomed |

| MOQ | 1 PCS |

| Certification | GS |

1. who are we?

We are based in Shanghai, China, start from 2016,sell to Southeast Asia(25.00%),North America(20.00%),Western Europe(15.00%),Oceania(10.00%),South America(10.00%),Mid East(10.00%),Eastern Europe(5.00%),Africa(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Diamond ND MCD tool,PCD woodworking tools,PCD CBN inserts and tools, carbide bits, wheels.saws

4. why should you buy from us not from other suppliers?

We are an enterprise integrating R & D, production and sales. It is a professional manufacturer of precision diamond tools and tools.We can produce according to your drawings, so welcome OEM!

5. what services can we provide?

Accepted Delivery Terms: FOB; EXW CIF, DAP, DDP

Accepted Payment Currency:USD,HKD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Russian