Specification:

PCD chipping: mainly used for aluminum processing, also can process copper, plastic, non-ferrous metals, etc, with good chip effect.

PCD-(Polycrystalline Diamond) is mainly used in aluminum processing, but also can process copper, brass, plastic, non-ferrous metals and so on.

R0.2:suitable for finishing.

R0.4:suitable for finishing to semi finishing.

R0.8:suitable for semi finishing to rough machining.

Feature :

CBN:

Multi corner available, cost saving.

High hardness, powerful cutting.

Strong wear resistance and high finish.

PCD:

High hardness, good cutting effect

Strong wear resistance and high finish.

WE PROVIDE

Milling Insert:APMT APKT RDMT RPMT LNMU BLMP SEKT SDMT SOMT SEKN SEEN SPKN TPKN TPKR TPMR 3PKT WNMU SNMU ONMU AOMT JDMT R390 BDMT

Turning Insert: CNMG CCMT SNMG SCMT WNMG TNMG TCMT DCMT DNMG VNMG VBMT KNUX

Grooving Insert: MGMN MRMN N151 N123 ZTFD TDC2 TDC3 TDC4

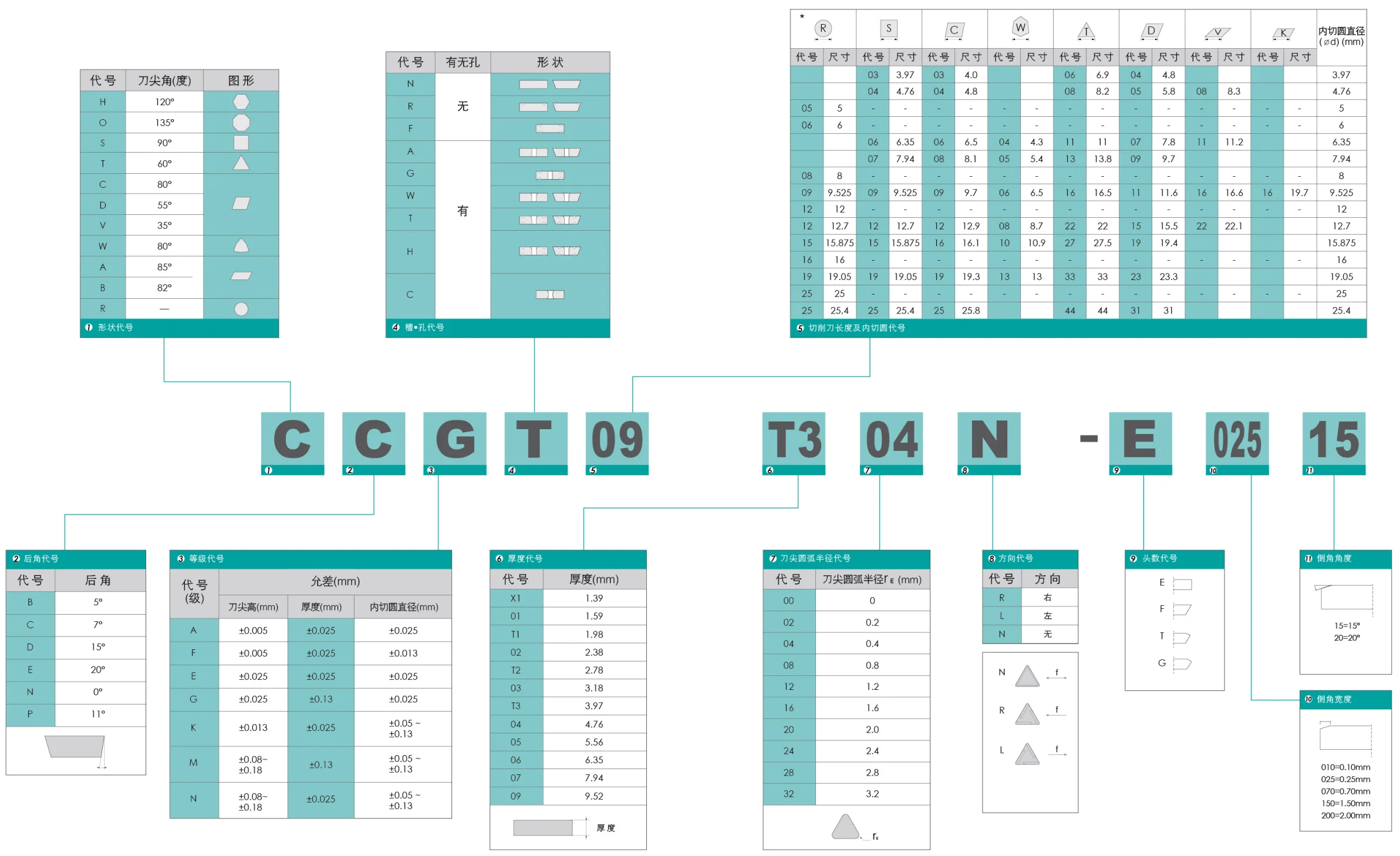

Insert for alu: APGT APKT CCGT DCGT VCGT RCGT SCGT SEHT TCGT ZTED

Threading Insert: 11IR 11ER 16ER 16IR 22ER 22IR

U drill Insert: SPMT WCMX WCMT

Cast iron Insert: CNMA DNMA SNMA TNMA VNMA WNMA

| Parameter Table | |||

| PCD | CBN | ||

| Heat Resistance/ºC | 700-800 | Heat Resistance/ºC | 1400-1500 |

| Compressive Strength/Mpa | 600-1100 | Compressive Strength/Mpa | 500-800 |

| Fracture Toughness/Mpa.m1/2 | 9 | Fracture Toughness/Mpa.m1/2 | 9 |

| Hardness | >8000HV | Hardness | 3500-5000HV |

| Thermal Conductivity/[W/(m.k)] | 700 | Thermal Conductivity/[W/(m.k)] | 200-300 |

| Thermal Expansion Coefficient/(10-6/K) | 0.9-1.18 | Thermal Expansion Coefficient/(10-6/K) | 3.5-4.8 |

| Suitable materials for processing | PCD:Aluminum and its aluminum alloys, copper and its copper alloys, hard alloys, titanium/magnesium/zinc/lead and other non-ferrous metals. Glass fiber, carbon fiber reinforced plastic and other non-metallic materials. | ||

| CBN:hardened steel(45-65HRC),bearing steel(60-62HRC),high-speed steel(>62HRC),tool steel(57-60HRC),chilled cast iron,High-temperature alloy,High speed of difficult to machine materials,Replacing Grinding with turning. | |||

| Recommended processing parameters | |||||

| Type | Workpiece material | Hardness | Vc(m/min) | fn(mm/rev) | ap(mm) |

| CBN | Gray Iron | HB170-230 | 500-1500 | 0.1-0.4 | 0.1-1.5 |

| Nodular Cast Iron | HB240-300 | 200-400 | 0.1-0.4 | 0.1-1.5 | |

| Alloy Cast Iron | HB240-300 | 150-300 | 0.05-0.4 | 0.1-1.5 | |

| Iron Base Alloys | HRC45-50 | 50-150 | 0.05-0.4 | 0.05-0.5 | |

| Hardened Steel | HRC45-65 | 80-200 | 0.05-0.2 | 0.05-0.2 | |

| Heat-Resisting Alloy | 50-200 | 0.05-0.2 | 0.05-0.2 | ||

| PCD | Aluminum and its aluminum alloys | 200-3000 | 0.05-0.5 | 0.05-1.0 | |

| Non-Metallic Materials | 100-500 | 0.05-0.5 | 0.05-1.0 | ||

| Cemented Carbide | 20-30 | 0.05-0.2 | 0.05-0.2 | ||

PCD STANDARD TOOLS

Efficient based on continuous improvement of professional work.

PCD consist of 99.9% carbon isotope C12. Its Thermal performance is 50% better than natural diamond and 2 times faster than copper. Its physical property is also the best.

CBN STANDARD TOOLS

Precision based on persuit of perfect professional work.

CBN is non-natural matter formed with CBN and agglutinant sintering in the high temperature and pressure. Its hardness is second only to diamond, and has good heat conductivity, wear resistance, high thermal stability and excellent chemical stability, CBN is ideal for cutting iron-based metal material.

CUSTOM SPECIAL TOOLS

We are working based on efficiency, high-precision and specialized custom-made. According to the sector demand, will be selected and supported to the production and manufacture of some products. Such as diesel engine, automobile engine. This technology makers our clients work easy. Using PCD or CBN raw material, and specialized custome-made for you, can be used for cutting work of non-ferrous, other metal, aluminium alloy and some other non-metallic material. By using diamond cutting tools, you can obtain faster cutting process and longer tool life. The surface-quality and working accuracy of the processed material will be better.

1. who are we?

We are based in Shanghai, China, start from 2016,sell to Southeast Asia(25.00%),North America(20.00%),Western Europe(15.00%),Oceania(10.00%),South America(10.00%),Mid East(10.00%),Eastern Europe(5.00%),Africa(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Diamond ND MCD tool,PCD woodworking tools,PCD CBN inserts and tools, carbide bits, wheels.saws

4. why should you buy from us not from other suppliers?

We are an enterprise integrating R & D, production and sales. It is a professional manufacturer of precision diamond tools and tools.We can produce according to your drawings, so welcome OEM!

5. what services can we provide?

Accepted Delivery Terms: FOB; EXW CIF, DAP, DDP

Accepted Payment Currency:USD,HKD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Russian